-

What are the advantages of Jiangmen packaging equipment

2020-10-08 922

Automatic packaging machine equipment is easy to preserve the quality of products and transport, by people's love and recognition. The automation level of oso is constantly improving in the manufacturing industry, and its application scope is expanding. Automatic operation in packaging machinery industry is changing the action method of packaging process and the processing method of packaging containers and materials. The automatic control packaging system can greatly improve the production effi

-

How to adjust the cutter of Jiangmen packing equipment

2020-10-08 957

1) the adjustment knife seat of end seal and cutter has been carefully adjusted and strictly checked before delivery. Under normal circumstances, there is no need to adjust it. If it is necessary to adjust the knife seat, first use two pieces of white paper with a carbon paper in the center to investigate the indentation pattern. If the indentation is uniform and the lines are clear, the cutter seat is in the correct position and does not need to be adjusted. Otherwise, it is necessary to adjust

-

What are the functions of Jiangmen packaging materials

2020-10-08 807

Packaging material protection function is a product from the end of packaging to the arrival of customers, all through the loading and unloading, transportation, storage, display and other links. In every link, there are many factors causing package damage. Packaging protection refers to the need to avoid the loss of product quality and quantity caused by these damages in the logistics process, so as to ensure the smooth realization of product value and application value. Packaging material is t

-

Jiangmen packing material tells you the advantage of inner lining with pearl cotton board

2020-10-08 791

The inner packing made of Jiangmen packing material plate is a kind of cushioning inner packing with certain characteristics of shock resistance, moisture resistance, sound insulation and heat insulation. Especially used in handicrafts, pearl cotton board and other decorative fabrics, flannelette, with impact maintenance effect, is also the development trend of packaging. Because the pearl cotton board is a bubble body, it is waterproof and sound-proof, moisture-proof, shock-proof, corrosion-res

-

Several requirements of Jiangmen packaging material selection

2020-10-08 817

In the early days of packaging. There is no much consideration on whether the information about food packaging bags, self-supporting bags and other packaging bags will affect the environment. This led to the release of various packaging restrictions. With the improvement of people's sense of environmental protection. There are also requirements for information on packaging. Green packaging is the strategy of environmental protection. The selection of information is crucial. It determines the deg

-

Jiangmen packing material tells you the specific production process of bubble bag

2020-10-08 798

Mold making and processing: according to the requirements or sample specifications, the first step is to make a good blister mold. Generally, gypsum is used to make the blister packaging mold. However, Dongguan packaging material also uses wood carving and metal carving products as the mold. After the gypsum mold is made, first let it be naturally dry or dry, and then use 1-2 mm drill according to the specific conditions of the convex and concave surface of the product Many small holes should be

-

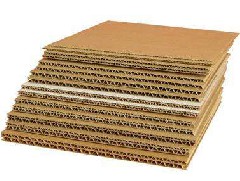

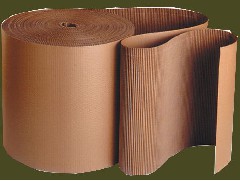

What are the classification of packaging materials in Jiangmen

2020-10-08 901

Paper packaging materials: packaging paper honeycomb paper, paper bag paper, desiccant packaging paper, honeycomb paperboard, kraft paper industrial paperboard, honeycomb paper core; plastic packaging materials: PP packaging belt, PET packaging belt, tear film, winding film, sealing tape, heat shrinkable film, plastic film, hollow plate; composite soft packaging materials: soft packaging, aluminum film, iron core wire, aluminum foil composite film, vacuum Aluminum coated paper, composite film, c

-

What are the classification and uses of Jiangmen packaging materials

2020-10-08 863

Packaging materials occupy a very important position in the material industry. The value of packaging industry in developed countries now accounts for more than 2% of GDP. Now our country also needs to consume a lot of product packaging every year. In recent years, with the progress of people's living standards, especially people's environmental protection is getting more and more attention, so there are higher requirements for packaging, and the voice of green packaging is getting higher and hi

-

Causes of over high temperature of motor in Jiangmen packaging equipment

2020-10-08 883

What is the reason for the high temperature of the mechanical motor of Jiangmen packaging equipment? The high temperature rise of the motor of vacuum packaging machine not only shortens the service life, but also causes fire when it is severe. If the temperature rise of the motor is too high, please stop it immediately. Today, Shanghai Youte to talk about the causes of excessive temperature rise: 1. Serious imbalance of three-phase voltage. Check whether the stator winding is short circuited bet

-

Jiangmen packing equipment tells you how to use wrapping machine

2020-10-08 865

1. The inner chain and the inner chain of the winding machine mould base should be smooth. When the film frame moves up and down, it can be eliminated by tensioning the chain. Other equipment, like packaging machines, should be regularly protected and kept smooth. 2. When the rotary table slows down or slips, open the motor cover of the rotary table, loosen the four connecting bolts on the reducer plate, and then adjust the two tension bolts clockwise to reach the required tension force, and the